No car with an internal combustion engine under the hood will drive if its fuel tank is empty. But there is not only fuel in this tank. It still needs to be delivered to the cylinders. For this, the engine fuel system has been created. Let’s consider what functions it has, how the vehicle of a gasoline unit differs from the version with which a diesel engine works. Let’s also see what modern developments exist that increase the efficiency of supplying and mixing fuel with air.

What is the engine fuel system?

The fuel system will refer to the equipment that allows the engine to operate autonomously due to the combustion of the compressed air-fuel mixture in the cylinders. Depending on the car model, engine type and other factors, one fuel system can be very different from another, but they all have the same principle of operation: they supply fuel to the corresponding units, mix it with air and ensure uninterrupted supply of the mix to the cylinders.

The fuel supply system itself does not provide autonomous operation of the power unit, regardless of its type. It is necessarily synchronized with the ignition system. The car can be equipped with one of several modifications that ensure timely ignition of the VTS. Details about the varieties and principle of operation of SZ in the car are described.

True, the aforementioned work of the vehicle refers to gasoline units. The diesel engine works differently. In short, it has no ignition system. Diesel fuel ignites in the cylinder due to hot air due to high compression. When the piston completes its compression stroke, the portion of air in the cylinder becomes very hot. At this time, diesel fuel is injected and the BTC is ignited.

Purpose of the fuel system

Any engine that burns VTS is equipped with a vehicle, the various elements of which provide the following actions on the car:

- Provide fuel storage in a separate tank;

- Takes fuel from the fuel tank;

- Clean the environment of foreign particles;

- Fuel supply to the unit in which it is mixed with air;

- Spray VTS into a working cylinder;

- Fuel return in case of excess.

The vehicle is designed so that the fuel mixture is supplied to the working cylinder at the moment when the combustion of the VTS will be most effective and the maximum efficiency of the engine will be removed. Since each engine mode requires a different timing and fuel delivery rate, engineers have developed systems that adapt to the engine speed and load.

Fuel system device

Most fuel delivery systems have a similar design. Basically, the classic scheme will consist of the following elements:

- Fuel tank or tank. Stores fuel. Modern cars receive more than just a metal container into which the road fits. It has a rather complex device with several components that ensure the most efficient storage of gasoline or diesel fuel. This system includes an adsorber, filter, level sensor and in many models an automatic pump.

- Fuel line. This is usually a flexible rubber hose that connects the fuel pump to other components in the system. In many machines, the tubing is partly flexible and partly rigid (this part consists of metal tubes). The soft tube constitutes the low pressure fuel line. In the metal part of the line, gasoline or diesel has a lot of pressure. In addition, a car fuel line can be conditionally divided into two circuits. The first is responsible for feeding the engine with a fresh portion of fuel, and is called fuel. In the second circuit (return), the system will drain excess gasoline/diesel fuel back to the gas tank. Moreover, such a design can be not only on modern vehicles, but also on those that have a VTS preparation type of carburetor.

- Petrol pump. The purpose of this device is to ensure constant pumping of the working medium from the reservoir to the sprayers or to the chamber in which the VTS is prepared. Depending on the type of engine installed in the car, this mechanism can be driven electrically or mechanically. The electric pump is controlled by an electronic control unit and is an integral part of the ICE (injection engine) injection system. A mechanical pump is used in older cars where a carburetor is installed in the engine. Basically, a gasoline internal combustion engine is equipped with a fuel pump, but there are also modifications of injection vehicles with a booster pump (in versions that include a fuel rail). The diesel engine is equipped with two pumps, one is a high pressure fuel pump. Creates high pressure in the line . The second pumps fuel, which facilitates the operation of the main supercharger. The pumps that create high pressure in diesel engines are driven by a pair of plungers.

- Fuel cleaner. Most fuel systems will have a minimum of two filters. The first provides rough cleaning and is installed in the gas tank. The second is designed for finer fuel purification. This part is installed in front of the inlet to the fuel rail, high pressure fuel pump or in front of the carburetor. These items are consumables and must be replaced periodically.

- Diesel engines also use equipment that heats the diesel oil before it enters the cylinder. Its presence is due to the fact that diesel fuel has a high viscosity at low temperatures, and the pump finds it more difficult to cope with its task and, in some cases, cannot pump fuel into the line. But for such units, the presence of glow plugs is also relevant. Read how they are different from spark plugs and why they are necessary.

Depending on the type of system, its design may include other equipment that provides finer work of fuel supply.

How does a car’s fuel system work?

Since there is a wide variety of vehicles, each of them has its own mode of operation. But the key principles are no different. When the driver turns the key in the ignition lock (if an injector is installed on the internal combustion engine), a faint hum is heard coming from the side of the gas tank. The fuel pump has worked. Increases the pressure in the pipe. If the car has a carburetor, then in the classic version the fuel pump is mechanical and until the unit starts to rotate, the supercharger will not work.

When the starter motor rotates the flywheel disc, all engine systems are forced to start synchronously. As the pistons move in the cylinders, the intake valves in the cylinder head open. Due to the vacuum, the cylinder chamber begins to fill with air in the intake manifold. At this time, gasoline is injected into the passing air stream.

When the timing valves close, a spark is applied to the compressed air/fuel mixture. This discharge ignites the BTS, during which a large amount of energy is released, pushing the piston to bottom dead center. Identical processes occur in adjacent cylinders and the engine begins to work autonomously.

This schematic principle of operation is typical for most modern cars. But other modifications of fuel systems can be used in the car. Let’s consider what their differences are.

Types of injection systems

All injection systems can be roughly divided into two:

- A variety for gasoline internal combustion engines;

- Variety for internal combustion diesel engines.

But even in these categories, there are several types of vehicles that will inject fuel in their own way into the air going to the cylinder chambers. Here are the key differences between each type of vehicle.

Fuel systems for gasoline engines

In the history of the automotive industry, gasoline engines (as the main units of motor vehicles) appeared before diesel engines. Since air is required to ignite gasoline in cylinders (without oxygen, not a single substance will ignite), engineers have developed a mechanical unit in which gasoline is mixed with air under the influence of natural physical processes. It depends on how well this process is done whether the fuel burns completely or not.

Initially, a special unit was created for this, which was located as close as possible to the engine in the intake manifold. This is a carburetor. Over time, it became clear that the characteristics of this equipment directly depend on the geometric characteristics of the intake tract and cylinders, so not always such engines can provide an ideal balance between fuel consumption and high efficiency.

In the early 50s of the last century, an injection analogue appeared, which provided forced metered injection of fuel into the air flow passing through the manifold. Let’s consider the differences between these two system modifications.

Carburetor fuel supply system

The carburetor engine is easy to distinguish from the injection engine. Above the cylinder head will be a flat “tray” that is part of the intake system and contains an air filter. This element is mounted directly on the carburetor. A carburetor is a multi-chamber device. Some contain gasoline, while others are empty, that is, they function as air channels through which a stream of fresh air enters the collector.

A throttle valve is installed on the carburetor. In fact, this is the only regulator in an engine of this type that determines the amount of air entering the cylinders. This element is connected through a flexible tube to the ignition distributor to correct the SPL due to vacuum. Classic cars used a device. On sports cars, one carburetor per cylinder (or one for two pots) could be installed, which significantly increased the power of the internal combustion engine.

Fuel supply occurs due to the suction of small portions of gasoline when the air flow passes through the fuel jets. The gasoline is absorbed by the stream and, due to a thin hole in the nozzle, the portion is distributed into small particles.

Additionally, this VTS flow enters the intake manifold tract in which a vacuum was formed due to the open intake valve and the piston moving downward. The fuel pump in such a system is needed only to pump gasoline into the corresponding cavity of the carburetor (fuel chamber). The peculiarity of this arrangement is that the fuel pump has a rigid coupling with the power unit mechanisms (it depends on the type of engine, but in many models it is driven by a camshaft).

So that the fuel chamber of the carburetor does not overflow and gasoline does not fall uncontrollably into the adjacent cavities, some devices are equipped with a return line. Allows excess gasoline to drain back into the gas tank.

Fuel injection system (fuel injection system)

Monoinjection has been developed as an alternative to the classic carburetor. This is a system with forced gasoline atomization (the presence of a nozzle allows you to divide a portion of fuel into smaller particles). In fact, this is the same carburetor, only an injector is installed in the intake manifold instead of the previous device. It is already controlled by a microprocessor, which also controls the electronic ignition system.

In this design, the fuel pump is already electric and generates high pressure, which can reach several bars (this characteristic depends on the injection device). Such a vehicle with the help of electronics can change the amount of flow entering the fresh air stream (change the composition of the VTS, deplete it or enrich it), so all injectors are much more economical than engines of carburetor with an identical volume.

Subsequently, the injector evolved into other modifications that not only increase the efficiency of gasoline spraying, but are also capable of adapting to different operating modes of the unit. Details about the types of injection systems are described. in a separate article … These are the main vehicles with forced gasoline atomization:

- Monoinjection. We have already briefly reviewed its characteristics.

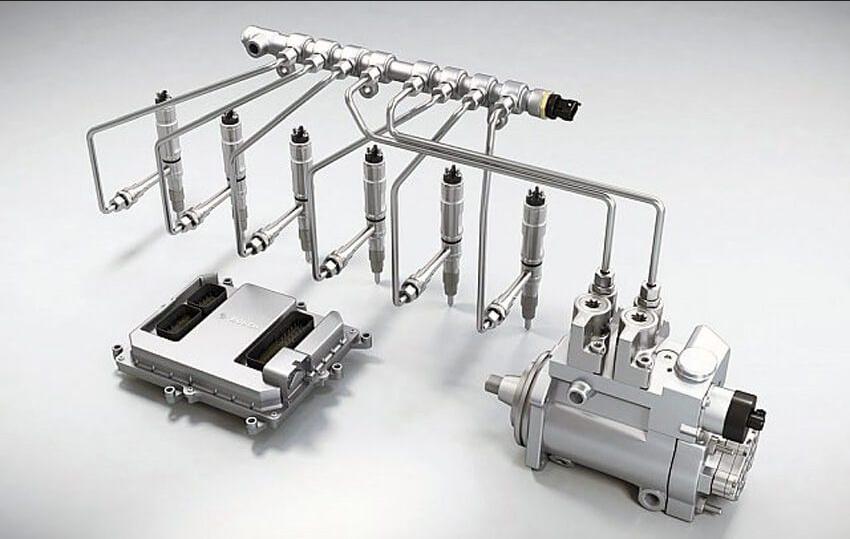

- Distributed injection. In short, its difference from the previous modification is that not one, but several nozzles are used for spraying. They are already installed in separate pipes from the intake manifold. Its location depends on the type of engine. In modern power plants, nozzles are installed as close as possible to the opening inlet valves. The individual atomizing element minimizes gasoline loss during operation of the intake system. In the design of this type of vehicle there is a fuel rail (a small elongated tank that acts as a tank in which the pressurized gasoline is located). This module allows the system to distribute fuel evenly through the injectors without vibration. In advanced motors, a more complex type of battery vehicle is used. This is a fuel rail, in which there is necessarily a valve that controls the pressure in the system so that it does not explode (the injection pump can create critical pressure for the pipes, since the pair of plungers works from a rigid connection to the power unit).

- Direct injection. This type refers to multipoint gasoline spray systems. Its peculiarity is that the injectors are not located in the intake manifold, but directly in the cylinder head. This arrangement allows automakers to equip the internal combustion engine with a system that shuts down several cylinders depending on the load of the unit. Thanks to this, even a very large engine can demonstrate decent efficiency, of course, if the driver uses this system correctly.

The essence of the operation of injection engines remains unchanged. With the help of a pump, gasoline is removed from the tank. The same mechanism or injection pump creates the pressure necessary for effective atomization. Depending on the design of the intake system, at the right time, a small portion of sprayed fuel is supplied through the nozzle (a fuel mist is formed, so the BTC burns much more efficiently).

Most modern vehicles are equipped with a ramp and a pressure regulator. In this version, fluctuations in the gasoline supply are reduced and it is distributed evenly between the injectors. The operation of the entire system is controlled by the electronic control unit in accordance with the algorithms built into the microprocessor.

Diesel fuel systems

Diesel engine fuel systems are exclusively direct injection. The reason lies in the HTS ignition principle. In such a modification of engines, there is no ignition system as such. The design of the unit involves compressing the air in the cylinder to such an extent that it heats up to several hundred degrees. When the piston reaches top dead center, the fuel system sprays diesel fuel into the cylinder. Under the influence of high temperatures, a mixture of air and diesel fuel ignites, releasing the energy necessary for the movement of the piston.

Another feature of diesel engines is that, compared to gasoline analogues, their compression is much higher, therefore, the fuel system must create an extremely high pressure of diesel fuel in the rail. For this, only a high-pressure fuel pump is used, which works on the basis of a pair of plungers. A malfunction of this element will prevent the engine from working.

The design of this vehicle will include two fuel pumps. One simply pumps diesel fuel into the main and the main creates the required pressure. The most effective device and action is the Common Rail fuel system. She is described in detail in another article.